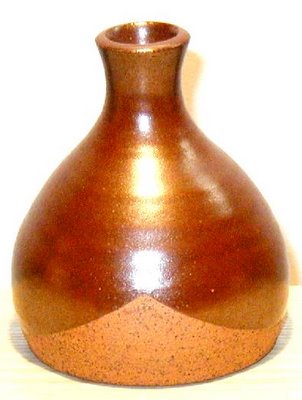

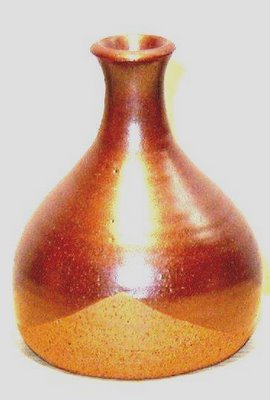

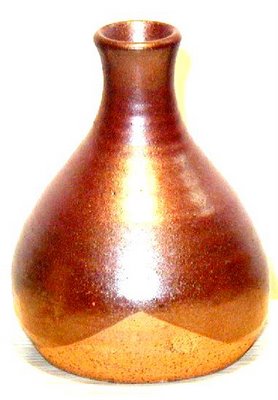

Redart

deposits from a prehistoric lake bed.

Contains 40% illite, 10% kaolinite, 7% iron oxide,

and 15% mixed layered clays.

Manufactured by Cedar Heights Clay Division

of Resco Products Inc.; comes from Ohio.

Relatively low plasticity, but good brick-red color

(best color at c/02 [IMC]).

Analyses:

Obstler: % 0.4 Na2O 4.07 K2O 1.55 MgO

0.23 CaO 16.41 Al2O3 64.27 SiO2 1.06 TiO2

7.04 Fe2O3 4.92 LOI

Cooper & Royle: (Appendix 8) % 0.40 Na2O

4.07 K2O 1.55 MgO 0.23 CaO 16.41 Al2O3

64.27 SiO2 1.06 TiO2 7.04 Fe2O3 4.78 LOI

Chappell: (slight variance from C&R)

% 4.07 Na2O 0.40 K2O 1.55 MgO 0.23 CaO

16.41 Al2O3 64.24 SiO2 1.06 TiO2 7.04

Fe2O3 4.78 LOI

Cushing: (probable error in SiO2) % 0.40 Na2O

4.07 K2O 1.55 MgO 0.23 CaO 16.4 Al2O3

54.3 SiO2 1.06 TiO2 7.04 Fe2O3 0.17 P2O5

4.78 LOI 0.24 SO3

Tichane (AG, TCB, CB): % 0.4 Na2O 4.1 K2O

1.6 MgO 0.2 CaO 16.4 Al2O3 64.3 SiO2 1.1 TiO2

7.0 Fe2O3 4.8 LOI

IMC: % 0.38 Na2O 4.15 K2O

1.59 MgO 0.26 CaO 15.51 Al2O3 64.95 SiO2

1.09 TiO2 7.05 Fe2O3 0.22 P2O5 4.80 LOI